Underwater ROVs and the price of Green Shipping.

One of the “hottest” current topics in the marine industry is green shipping. Alongside decarbonization, digitalization, autonomous shipping modules, blockchain technology, cyber-attacks, and changing trade patterns, green shipping has been highlighted by many in the maritime community, including the International Maritime Organization (IMO), the European Council for maritime Applied R&D (ECMAR), and the 2020 Nordic Maritime Expo in Finland, along with

Globally, marine shipping has been estimated to account for 3% of total carbon dioxide emissions, a relatively small amount as compared to other modes of shipping such as rail, road, and air transport. However, marine shipping’s more serious contributions are in sulfur (15% of total emissions) and particulate matter (11% of total emissions). These are mainly caused the sources of fuel used by the marine shipping industry, with heavy fuel oil, or HFO, dominating as a fuel source for half a century. Now the industry, with IMO’s encouragement (most notably it’s 2020 Sulfur limit), may pursue greener options.

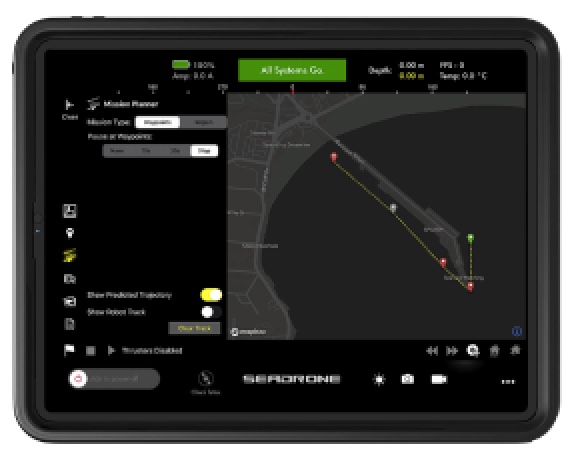

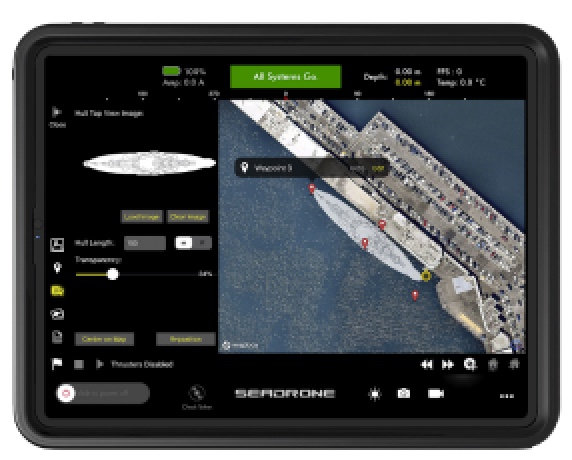

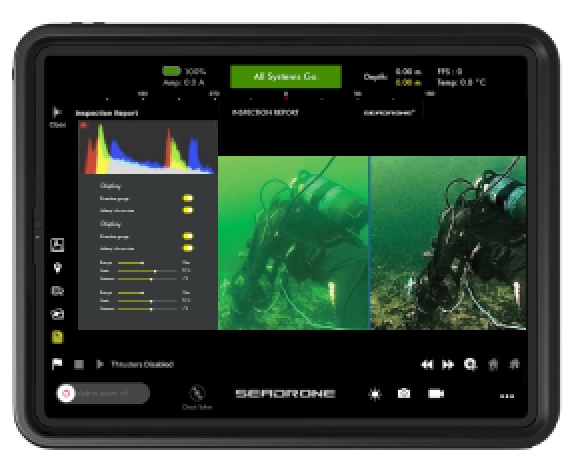

Robotic technology and underwater Remotely Operated Vehicles (ROVs) have possibilities for expansion in this space. Underwater ROVs such as the SeaDronePRO can cut the environmental footprint of ship inspections by lessening the resources required – namely human divers, time spent at port or in dry dock, and time taken for the inspection. Underwater ROVs can also more efficiently identify areas for improvement in a ship’s hull design, fuel use, and marine coatings with the use of photo/video documentation.

In a previous blog post, SeaDrone has highlighted the importance of marine coatings in working toward a greener marine shipping industry. Underwater ROVs can better identify potential problems in marine coatings and assist in their application and removal.

Some of the other latest technologies emerging in the world of green shipping, as highlighted by Marine Insight and others, include:

No Ballast System – a way to prevent harmful biofouling organisms from hitching a ride. This system creates a constant flow of local seawater from bow to stem below the waterline. Ship ballast tanks are replaced with longitudinal structural ballast trunks with one center tank, two intermediate tanks, and two side tanks.

LNG fuel for propulsion – While oil-based fuels remain the main fuel option for most vessels, the use of Liquefied Natural Gas or Liquid Natural Gas (LNG) as a fuel alone or combined with diesel can help ships meet air emission regulations. LNG fuel can also be used for auxiliary engines.

Water in fuel – Water in fuel added before its injection into the combustion chamber can reduce the temperature inside the cylinder liner, and can result in lower nitrous oxide compound emissions.

Sulfur scrubber system – an exhaust gas scrubber system which washes out Sulfur from the exhaust gas of the engine and reducing Sulfur emissions.

VLSFO fuel oil – Very Low Sulfur Fuel Oil (VLSFO) is a fuel option that also reduces Sulfur emissions.

Other Exhaust gas purifiers.

Advancing designs for Rudders and Propeller Systems – streamlined systems can reduce fuel consumption and improve vessel speed.

Speed Nozzle – improvements in propulsion efficiency and power savings for the ship.

Marine hull paint – See SeaDrone’s previous blog posts about this topic.

Waste Heat Recovery System – reduce fuel consumption by using waste heat to heat and generate steam, which can then be used for heating the cargo area, accommodation, and other areas.

Exhaust Gas Recirculation – nitrous oxide compound emissions can be reduced by recirculating the exhaust gas from the engine cylinder.

Improved pump and cooling water system – an optimized cooling system can decrease the resistance to flow, save electric power, and reduce fuel consumption.

Sandwich Plate System (SPS) – a process of composting two metals plates that avoids the usage of steel.

Robotic technology has its role to play in the greening of the marine industry. Besides within ship inspections and marine coatings, other highlighted uses for robotics in the greening of the maritime industry include cleanup, such as the U.S. Maritime Administration’s SEA-KIT partnership for robotic oil-cleanup vessels, and maintenance, such as fuel and oil service.

The world is moving increasingly toward a greener, more environmentally conscious future, and robotics are sure to factor in greatly to that future. The IMO has committed to halving its emissions by 2050. Norway, as part of its commitment to reduce greenhouse gas emissions by 40% by 2030, has established arguably the world’ most environmentally friendly shipping plan in DNV-GL’s Green Shipping Programme. The Green Ship Technology (GST) conference addresses environmental challenges faced by the maritime industry and will hold its annual conference on green ship technology in September 2021 in Copenhagen, Denmark.

Read more at SeaDronePro.com.

“One of the “hottest” current topics in the marine industry is green shipping.”

Marine Digital - Green-tech in Shipping Industry - Green Technologies for Shipping - https://marine-digital.com/article_green_ship

“Underwater ROVs such as the SeaDrone PRO can cut the environmental footprint of ship inspections.”

Marine Digital - Green-tech in Shipping Industry - Innovative technologies in Shipping - https://marine-digital.com/article_green_ship

Top view of main engine inside ship engine room.

Aerial view of oil tanker ship.