SeaDrone’s customers, such as AkzoNobel and RAMDrone Chile, never fail to show creativity when using the SeaDrone Inspector ROVs (remotely operated underwater vehicles). Cspect, a Belgium-based inspection company, takes this creativity to a new level with its custom-designed attachments and modifications to the SeaDrone Inspector 3 ROV. Using the team’s imagination, Cspect has developed new ways to inspect assets that deliver more value to its clients and open up new markets for ROV inspection. In this article, we will look at the range of attachments Cspect developed and how they have created new opportunities for the company.

The Bumper System

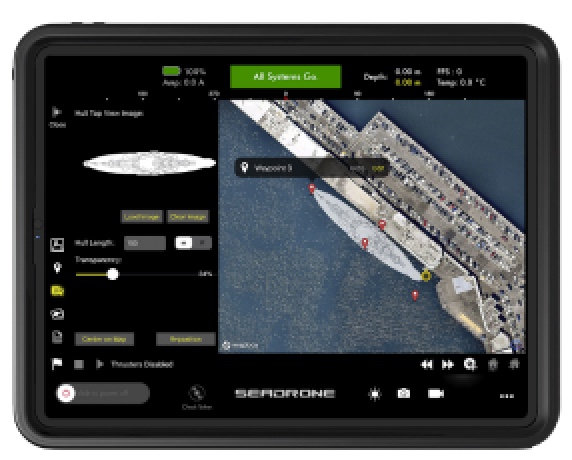

Cspect performs a range of asset monitoring services above and below water, including ballast tank inspections while the vessel is in operation, ship hull inspections for marine fouling and illicit substance transportation, and many others.

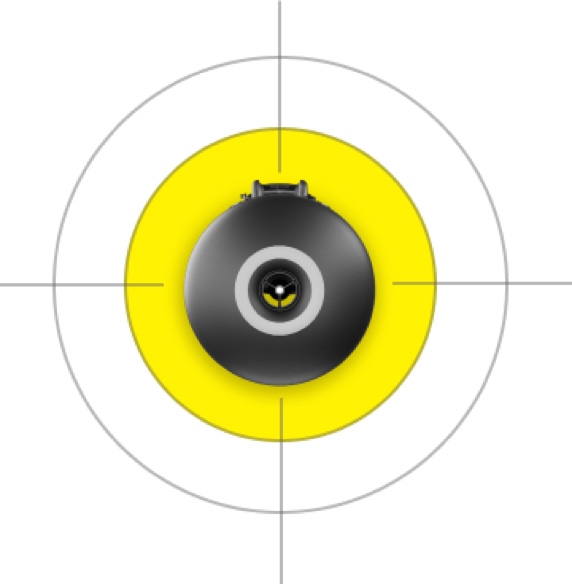

One of the innovative modifications and attachments that Cspect developed is a bumper system that attaches to the Inspector 3 ROV. The bumpers allow the ROV to approach the structure that Cspect is inspecting at a very close distance without crashing the ROV into the structure. This provides two benefits. First, the bumpers avoid damaging the vessel and the ROV. Second, the bumper system allows the ROV to stay at the same distance to the ship's hull at all times. This allows Cspect to capture photo and video footage at a consistent distance, which improves the quality of the survey reports that Cspect provides its clients.

Keeping a consistent distance is harder than it sounds. For example, when Cspect was inspecting a big bulk carrier in Rotterdam to check for marine fouling on the ship’s hull, the choppy waters made it challenging for the ROV to remain at a safe distance. Considering strict European standards for safety, according to Cspect co-founder Jurgen Moerman, a human diving crew probably would not have been allowed to inspect the hull during such rough waters. While the SeaDrone Inspector 3 is still able to perform inspections in turbulent waters, there is a higher risk of crashing.

The bumper system allowed Cspect to successfully perform the inspection in these choppy waters, which becomes safer than sending human divers out and saves the ship from having to be dry-docked.

The Positioning System

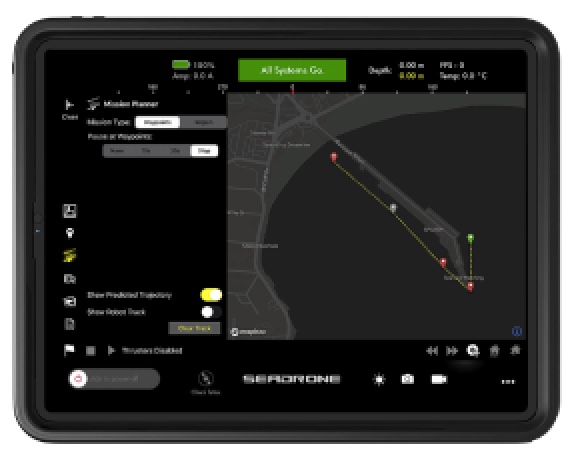

Controlling all ROVs can be challenging when ocean waters are choppy. The SeaDrone Inspector 3 was engineered to make maneuvering the ROV easier thanks to its multi-directional design which can handle cross-currents greater than 1 knot. Cspect was impressed by the Inspector 3 vehicle’s ability to sustain currents as high as 2.2 knots. To aid its performance in the ocean, Cspect added a positioning system that is designed and manufactured by Water Linked to the Inspector 3 ROV. This positioning system helps the pilot to know where the ROV is in the water at all times. The positioning system use beacons that they place into the water at the boundaries of the vessel or the structure that Cspect is inspecting. The pilot can detect the position of the ROV in relation to these beacons.

The Cleaning System

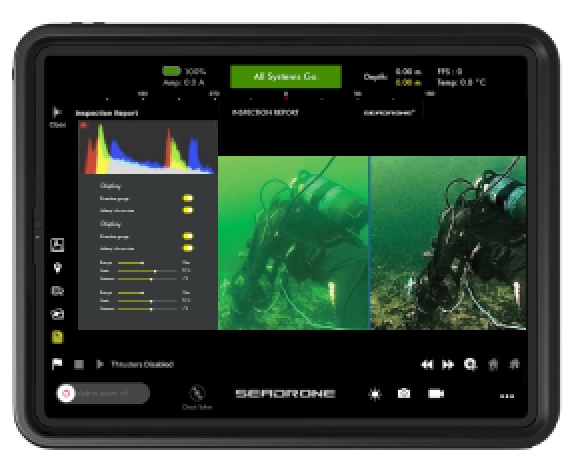

Cspect has a growing vision of the different inspection use cases it can tackle using the SeaDrone Inspector 3 vehicle. In addition to its inspections of ship hulls, ballast tanks, wind farms, quay inspections, and industry tank inspections, Cspect plans on developing a cleaning system that attaches to the Inspector vehicle. This cleaning tool can perform cavitation cleaning on sea chest gradings and storage tanks, which are complex areas for human divers to clean. The goal is to develop a cleaning tool that can remove corrosion and marine fouling, such as barnacles, using a high-pressure water hose.

The opportunity to use the SeaDrone Inspector 3 for inspecting ballast tanks would provide great benefits to Cspect clients because of how complex ballasts tanks can be for humans to inspect. Currently, ballast tank inspections require the tank to be empty for safety reasons. That means the water must be drained and the tank ventilated to ensure any toxic gases are removed. Cspect has the solution to inspect these ballast tanks without the expensive and cumbersome task of emptying and ventilating the tanks.

Cspect has developed many innovative modifications and attachments to extend the out-of-the-box SeaDrone Inspector 3 functionality. By building creative attachments and accessories to the ROV, Cspect extended the SeaDrone Inspector 3 vehicle’s ability to inspect assets using a bumper system, positioning system, and, in the future, a cleaning system. Using creativity to modify and add accessories to Inspector 3 is an example of the broad and exploratory uses that Cspect has found for the Inspector 3. We, at SeaDrone, are excited to see what new designs and innovations Cspect will add to the Inspector 3 vehicle in the future.